The writer of Ecclesiastes correctly surmised that there was no end to the business of making books. However, their publication in hard copy is another matter. Today’s commercial book market is dominated by the perfect-bound softcover book. Although hardcover books still appear regularly, these are almost entirely machine-produced. In appearance, many of these imitate the traditional hand-bound books of a century ago, but no machine-produced books have the durable qualities of the traditional “library” binding. Nor, indeed, do they have quite the same look, feel or smell. A traditional binding in leather or leather quarters is a thing of beauty. One can readily agree with Winston Churchill on this:

If you cannot read all your books, at any rate handle, or as it were, fondle them – peer into them, let them fall open where they will, read from the first sentence that arrests the eye, set them back on the shelves with your own hands, arrange them on your own plan so that if you do not know what is in them, you at least know where they are. Let them be your friends; let them at any rate be your acquaintances. If they cannot enter the circle of your life, do not deny them at least a nod of recognition.

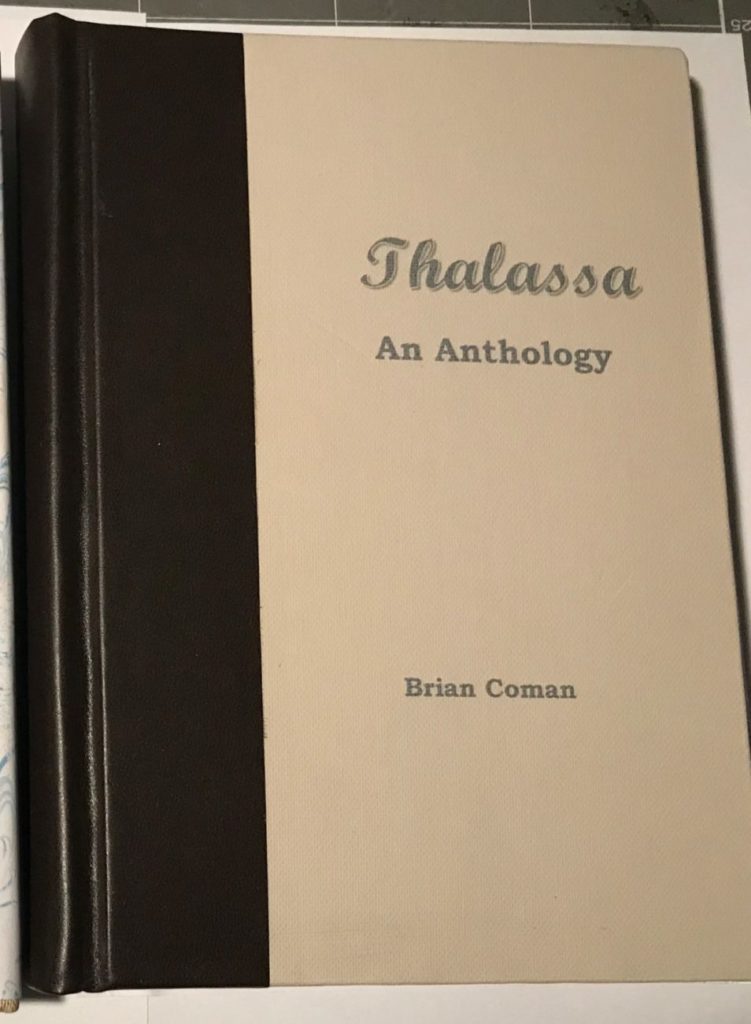

At Carbarita Press, the physical object is just as important as its contents. A good book will beckon to you.

The owner-operators of Carbarita Press, Coman and Oldmeadow oversee the whole production of their books from the initial writing of the text (or the selection and editing of the texts of others), through copy editing, layout and design, inkjet printing, collation of pages, to the sewing of signatures and the final binding in traditional styles.

Binding is done by Brian Coman who became interested in the traditional techniques of bookbinding in 2018. By his own admission he is a rank amateur, and points out that a skilled bookbinder of yore would spend many years of apprenticeship to a Master of the trade. His own learning ( such as it is) is largely via books written by master bookbinders from the early part of the last century.

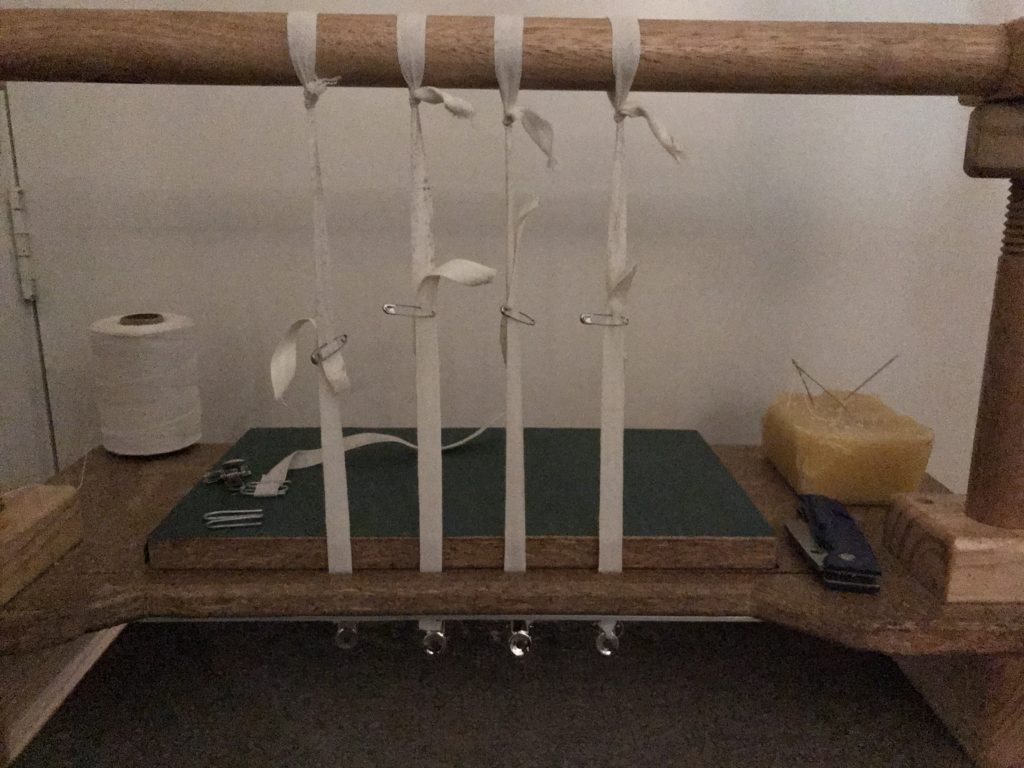

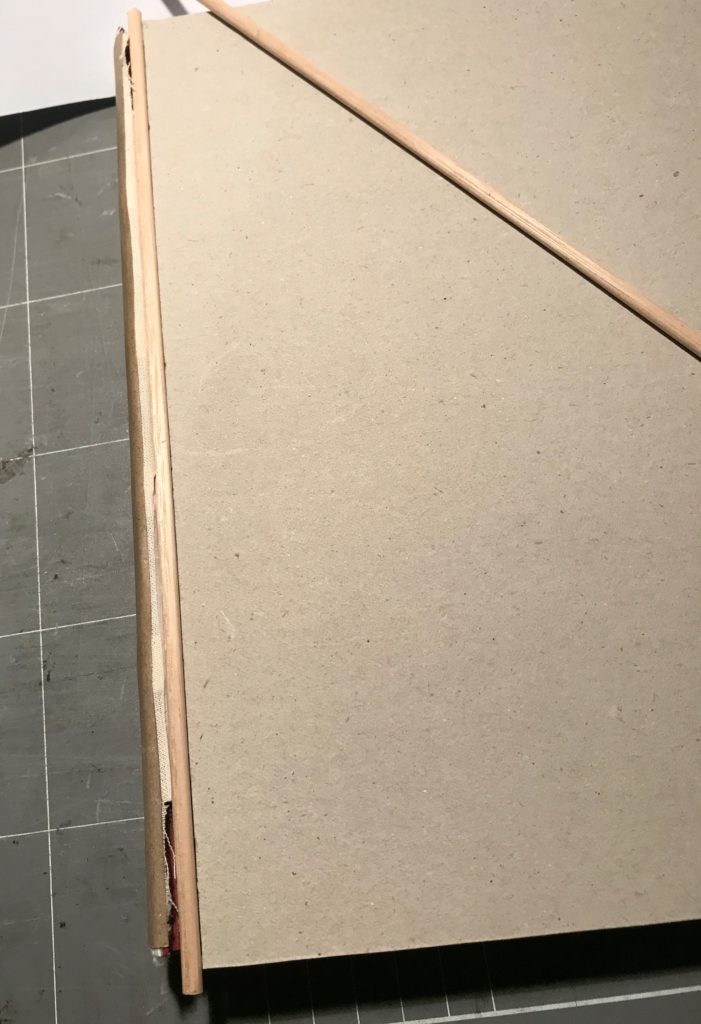

Due to the scarcity/high cost of much of the traditional equipment used, Brian has built most of his own presses, book ploughs and sewing frames. Some of the equipment is pictured below.

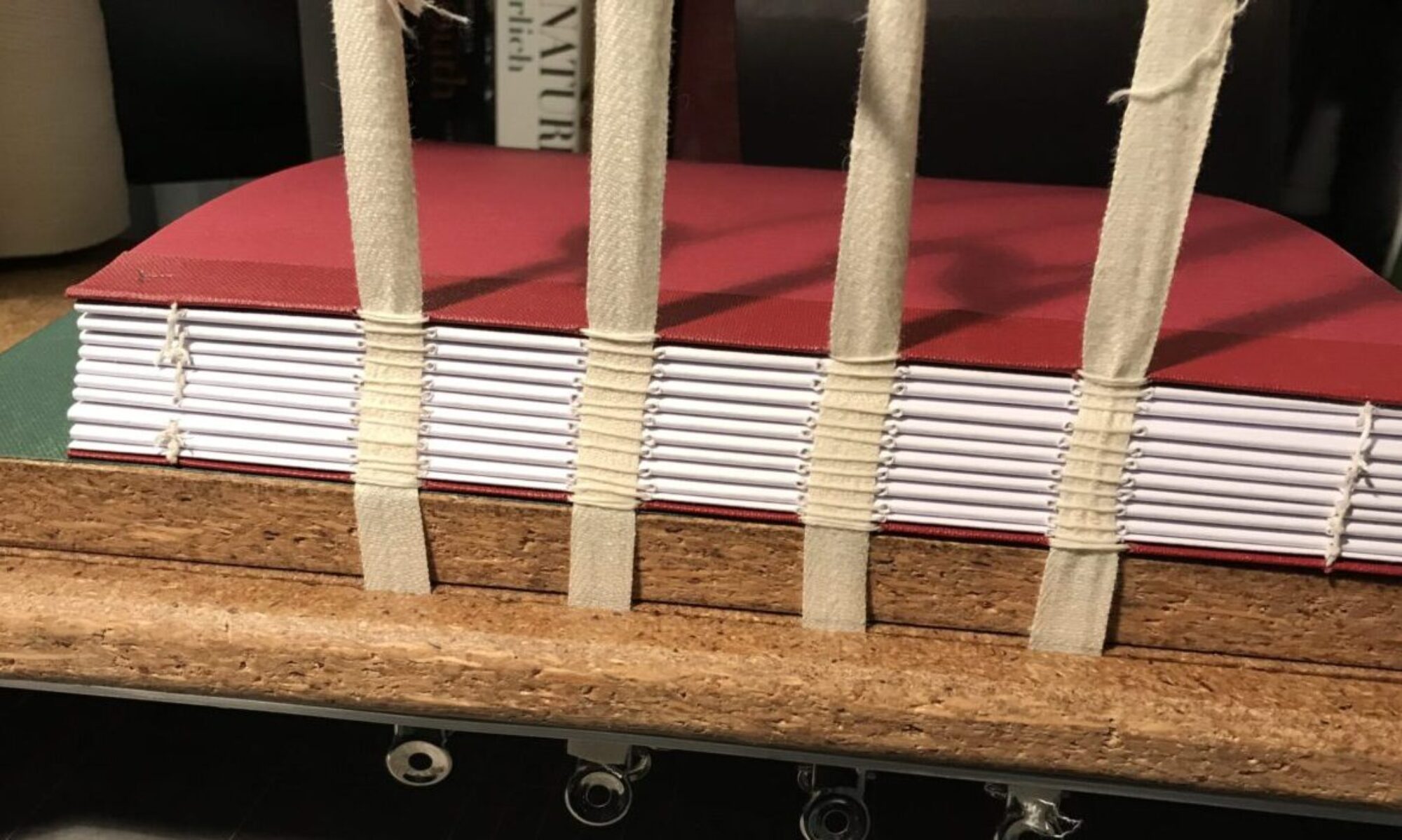

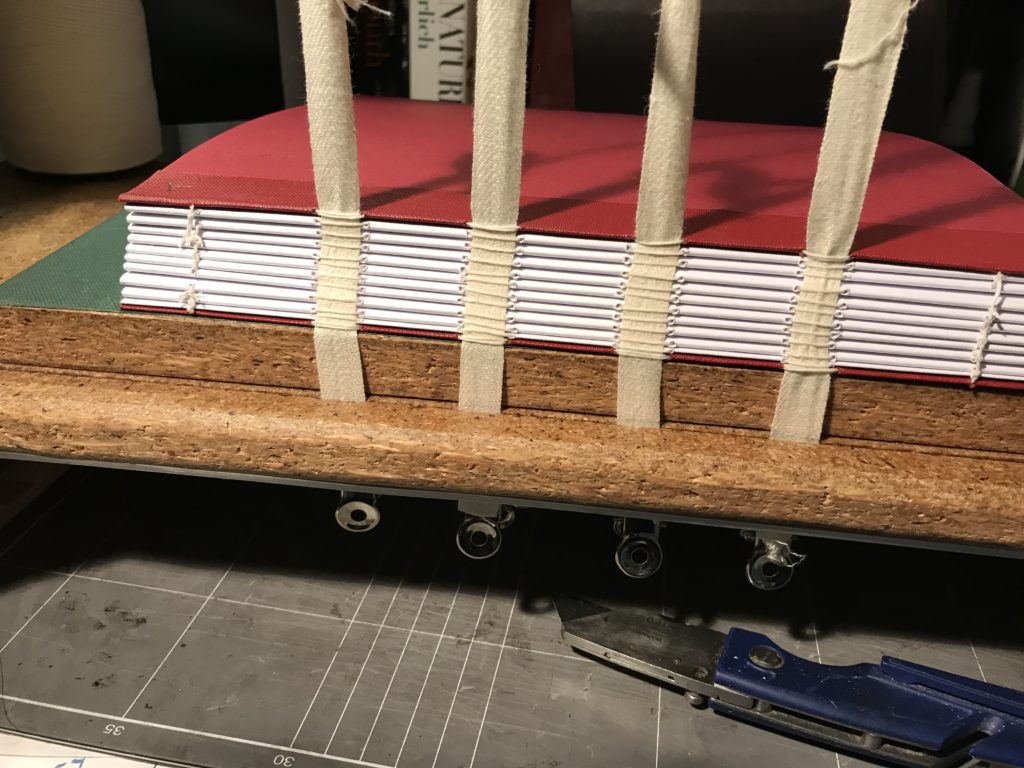

The manner of sewing depends upon the type of book. The most common method is often termed “sewn on tapes” and here, collections of folded pages (called signatures) are sewn as per the photograph below:

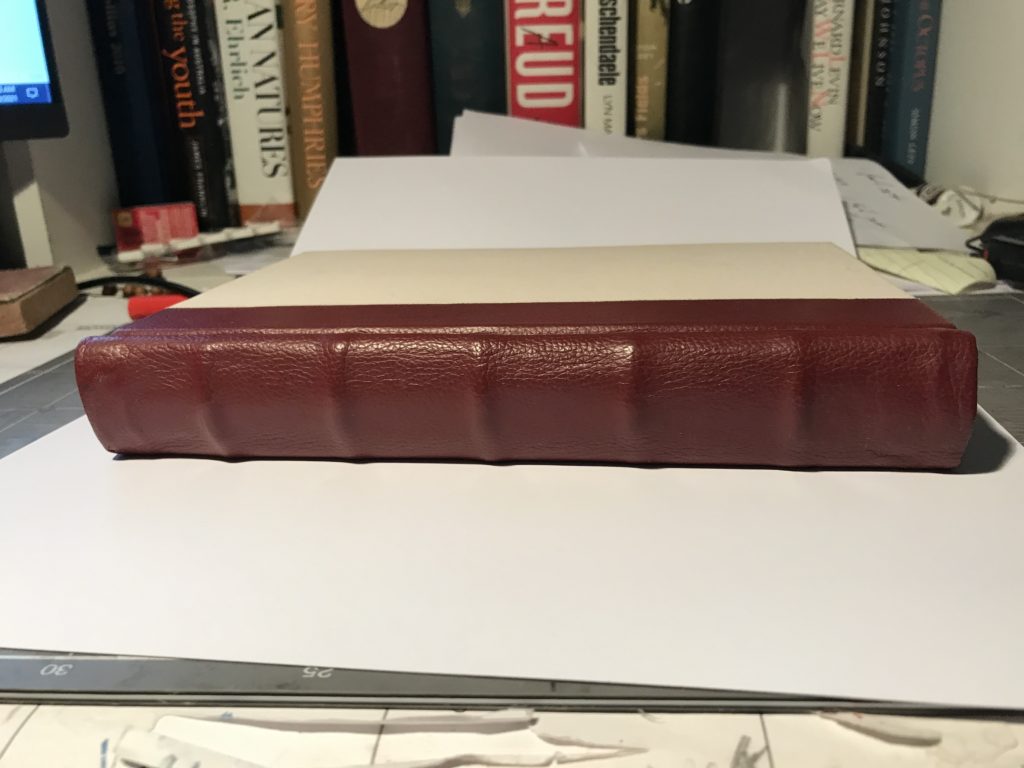

In this form of binding, the glued spine is usually “rounded and backed” to prevent excess swelling at the spine. This gives a characteristically rounded spine and a slightly concave foredge. Both are pleasing to the eye and make for a book with even sides.

Rounded and “backed” spine

The finished text block then has the boards attached to produce the standard “hard cover”.

Final covering in leather or bookcloth then completes the book.